Railway Lubricator: Job Description and Salary

Railway Lubricator Job Description Template

Railway Lubricator Job Description Railway lubricators are responsible for ensuring the smooth operation of railway tracks by applying lubricants to the moving parts of the tracks. Their primary duty is to prevent excessive friction and wear on the rails, which can lead to accidents and disruptions in train services. Railway lubricators are required to inspect the tracks regularly to identify areas that require lubrication. They use specialized equipment, such as handheld grease guns or automated lubrication systems, to apply lubricants to the specified parts of the tracks. These lubricants help reduce friction between the wheels of the train and the tracks, allowing for smoother and quieter operation. In addition to lubricating the tracks, railway lubricators also monitor the performance of the lubrication systems and make necessary adjustments or repairs when needed. They need to have a good understanding of different types of lubricants and their applications to ensure the correct lubricant is used for each specific part of the track. Attention to detail and adherence to safety procedures are crucial for railway lubricators. They must be able to work effectively under pressure and in various weather conditions. Additionally, they need to communicate effectively with other railway personnel, such as track maintenance workers and train operators, to coordinate lubrication activities and address any concerns or issues that may arise. Overall, railway lubricators play a vital role in maintaining the safety and efficiency of railway tracks. Their work significantly contributes to the smooth operation of train services and the prevention of accidents caused by excessive friction and wear on the tracks.Railway Lubricator Responsibilities

Railway Lubricator Requirements

How Much Does A Railway Lubricator Make?

Railway Lubricator Salary

| Job Title | Salary |

|---|---|

| Railway Lubricator | $35,000 – $45,000 per year |

A railway lubricator is responsible for applying lubricants to the moving parts of trains and ensuring their smooth operation. They work in the maintenance department of railway companies and play a crucial role in preventing mechanical failures and reducing friction within the rail system.

The salary range for a railway lubricator is typically between $35,000 and $45,000 per year. This may vary depending on factors such as experience, location, and the size of the railway company. Entry-level lubricators may start at the lower end of the salary range, while those with more experience and expertise may earn higher salaries.

Overall, being a railway lubricator can be a rewarding career path for individuals interested in the transportation industry and mechanical maintenance. It offers stable employment and opportunities for growth within the railway sector.

Railway Lubricator Salaries by Country

Top Paying Countries for Railway Lubricator

| Country | Average Salary |

|---|---|

| United States | $65,000 |

| Switzerland | $60,000 |

| Australia | $55,000 |

| Canada | $50,000 |

| Germany | $45,000 |

A railway lubricator is responsible for ensuring smooth operations of trains by applying lubricants to various components. The salary of a railway lubricator can vary significantly depending on the country of employment. According to available data, the top paying countries for railway lubricators are the United States, Switzerland, Australia, Canada, and Germany. These countries offer average salaries ranging from $45,000 to $65,000 per year. It is important to note that these figures may vary based on factors such as experience, qualifications, and the specific railway company.

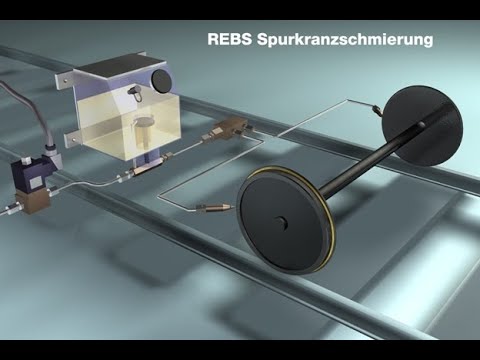

A video on the topic Railway Lubricator

Video Source : REBS Oil Air LubricationInterview Questions for Railway Lubricator

1. What is the role of a Railway Lubricator?

A Railway Lubricator is responsible for applying lubricants to various parts of the train, such as wheel bearings, axles, and other moving components. This helps reduce friction, prevent wear and tear, and ensure smooth operation of the train.

2. What are the essential skills required for this role?

The essential skills required for a Railway Lubricator include knowledge of different types of lubricants, the ability to interpret technical manuals and diagrams, good hand-eye coordination, attention to detail, and the ability to work in a fast-paced environment.

3. How do you ensure proper lubrication of train components?

To ensure proper lubrication, I follow the manufacturer’s guidelines and use the recommended lubricants. I also inspect the components regularly, looking for signs of wear or inadequate lubrication, and apply the lubricants in the appropriate amounts and intervals.

4. How do you handle different types of lubricants?

I am familiar with the properties and applications of various lubricants used in the railway industry. I ensure that I use the correct lubricant for each specific component and follow the safety protocols for handling and storing lubricants.

5. How do you maintain records of lubrication activities?

I maintain detailed records of lubrication activities by documenting the type and amount of lubricant used, the date and time of application, and the specific components lubricated. This helps track maintenance schedules, identify potential issues, and ensure compliance with regulations.

6. How do you prioritize lubrication tasks?

I prioritize lubrication tasks based on the manufacturer’s recommendations and the train’s maintenance schedule. I also consider the specific components that require immediate attention or those that are critical for the train’s safe operation.

7. How do you ensure safety while performing lubrication tasks?

I follow all safety protocols, such as wearing the required personal protective equipment (PPE), using the appropriate tools, and working in designated areas. I also make sure to apply lubricants only to the necessary components and avoid any contact with electrical or sensitive parts.

8. How do you handle emergency lubrication situations?

In case of emergency lubrication situations, I prioritize the safety of passengers and crew. I quickly assess the situation, identify the critical components requiring immediate lubrication, and take prompt action to ensure the train can continue to operate safely.

9. How do you stay updated with the latest lubrication techniques?

I stay updated with the latest lubrication techniques by regularly attending training sessions, workshops, and seminars related to railway lubrication. I also keep myself informed about industry advancements through professional networks, trade publications, and online resources.

10. Can you describe a challenging situation you faced as a Railway Lubricator and how you resolved it?

One challenging situation I faced was when a train experienced excessive wheel wear due to inadequate lubrication. To resolve the issue, I thoroughly inspected the affected components, identified the specific lubricant requirements, and applied the appropriate lubricant in the correct amount and intervals. I also recommended implementing a more stringent lubrication schedule to prevent similar issues in the future.

The Best Universities For The Railway Lubricator Profession.

- Massachusetts Institute of Technology (MIT)

- Stanford University

- University of Cambridge

- University of Oxford

- California Institute of Technology (Caltech)

- Harvard University

- Princeton University

- University of Chicago

- Imperial College London

- University of California, Berkeley